Copper impregnated graphite yog tsim los ntawm graphite thiab tooj liab hais. Ntawm lawv, graphite yog cov khoom siv carbonaceous, uas tuaj yeem muab faib ua ntuj graphite thiab graphite dag. Daim ntawv siv lead ua ntawm ntuj graphite yog daim ntawv hexagonal, nrog lub siab crystallinity thiab siab thermal conductivity. Nws yog cov khoom siv thermal conductivity zoo heev. Artificial graphite yog npaj los ntawm high-temperature sintering thiab lwm yam txheej txheem, thiab muaj cov yam ntxwv ntawm zoo homogeneity thiab siab zog.

Copper particles muab tooj liab thiab graphite los ntawm cov txheej txheem tshwj xeeb los tsim cov tooj liab-impregnated graphite. Lub hav zoov ntawm tooj liab tuaj yeem tsis tsuas yog txhim kho cov conductivity ntawm graphite, tab sis kuj txhim kho nws lub zog thiab hardness, yog li txhim kho nws cov khoom siv kho tshuab thiab hnav tsis kam. Tsis tas li ntawd, tooj liab hais tuaj yeem txo qhov kev tiv thaiv ntawm graphite thiab txhim kho nws cov thermal conductivity.

Cov khoom siv ntawm tooj liab-impregnated graphite muaj ntau yam, uas tuaj yeem muab faib ua phaj, yeeb nkab, hmoov thiab lwm yam ntaub ntawv.

Phaj yog ib qho ntawm cov khoom siv ntau tshaj plaws. Nws yog tsim los ntawm graphite thiab tooj liab hmoov los ntawm kev kub kub kub nias txheej txheem. Lub thickness yog feem ntau ntawm 1 hli thiab 6 hli. Qhov ntev thiab dav tuaj yeem kho raws li qhov xav tau tiag tiag. Qhov saum npoo ntawm lub phaj yog du thiab zoo ib yam, thiab tuaj yeem ua tiav, ua tiav thiab xuas nrig ntaus kom tau raws li qhov xav tau ntawm kev siv sib txawv.

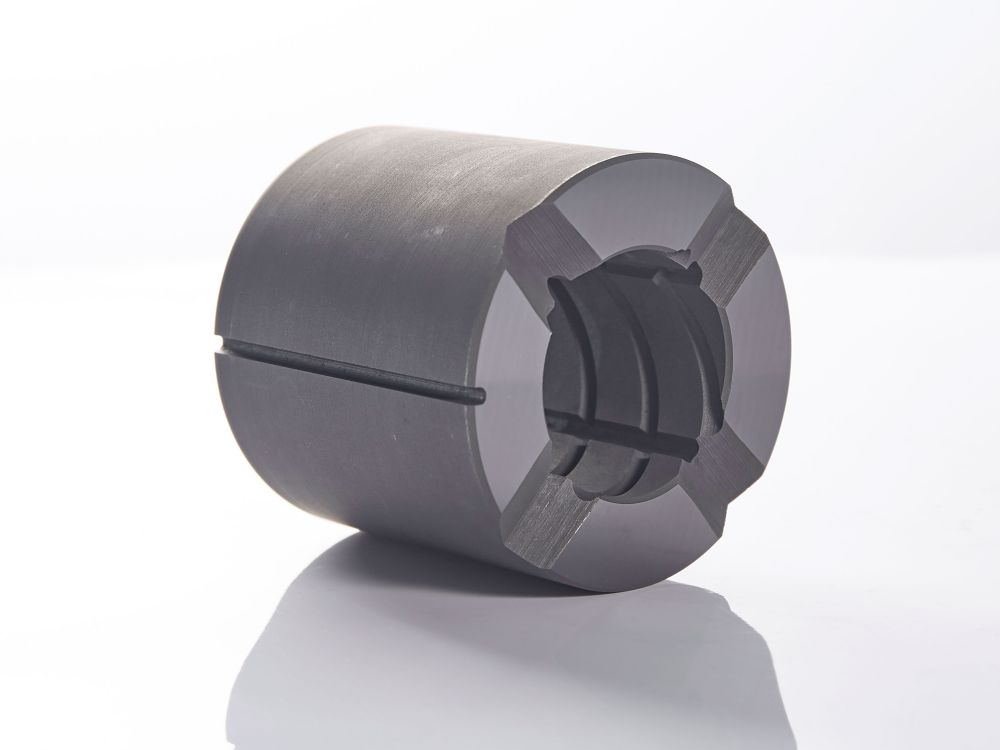

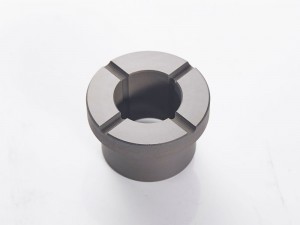

Cov yeeb nkab yog tsim los ntawm extrusion tom qab sib tov graphite thiab tooj liab hais. Nws sab hauv thiab sab nrauv yog du thiab sib xws. Nws tuaj yeem ua tiav nrog cov qhov hauv thiab sab nraud los tsim cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov roj hluav taws xob siab-rau-siv transformers thiab lwm yam khoom siv.

Cov hmoov yog ua los ntawm graphite thiab tooj liab hais los ntawm kev sib tsoo tshwj xeeb. Lub particle loj ntawm cov hmoov tuaj yeem hloov kho raws li qhov xav tau tiag tiag. Nws muaj ntau cov ntsiab lus sib cuag thiab zoo conductivity. Nws tuaj yeem siv dav hauv cov khoom siv hluav taws xob, cov khoom siv roj teeb thiab lwm yam haujlwm.

Kev tsim cov txheej txheem ntawm tooj liab graphite yog qhov yooj yim, feem ntau suav nrog cov kauj ruam hauv qab no:

1. Cov ntaub ntawv npaj: tooj liab hmoov thiab graphite hmoov yuav tsum tau tov nyob rau hauv ib qho kev faib ua feem, thiab ib tug npaum li cas ntawm lubricant thiab binder yuav tsum tau ntxiv.

2. Kev npaj ntawm lub cev molding: nias cov khoom sib xyaw rau hauv lub cev molding tsim nyog rau kev ua haujlwm.

3. Kev ziab thiab kev ua haujlwm: ziab cov molding, thiab tom qab ntawd txheej txheem, xws li tig, milling, drilling, thiab lwm yam.

4. Sintering: sintering cov txheej txheem ua cov khoom siv tooj liab graphite.

Cov yam ntxwv tseem ceeb ntawm tooj liab-impregnated graphite yog raws li nram no:

(1) Zoo conductivity: tooj liab impregnated graphite muaj ntau ntawm tooj liab hais, uas ua rau nws conductivity zoo heev.

(2) Cov khoom siv kho tshuab zoo: muaj cov khoom tooj liab txhim kho lub zog thiab hardness ntawm graphite, ua rau nws muaj cov khoom siv zoo.

(3) Zoo hnav tsis kam: lub xub ntiag ntawm tooj liab tuaj yeem txhim kho qhov hnav tsis kam ntawm graphite.

(4) Zoo corrosion kuj: graphite nws tus kheej muaj corrosion kuj zoo. Nrog rau qhov sib ntxiv ntawm tooj liab hais, nws cov corrosion kuj zoo heev.

(5) Zoo thermal conductivity: graphite yog cov khoom siv thermal conductivity zoo heev. Tom qab ntxiv cov tooj liab, nws cov thermal conductivity tseem zoo dua.

Copper-impregnated graphite muaj qhov zoo tshaj plaws conductivity thiab mechanical zog, thiab yog dav siv nyob rau hauv cov ntaub ntawv roj teeb, thermal tswj, electronics, machinery manufacturing thiab lwm yam kev lag luam.

Nyob rau hauv lub tshav pob ntawm cov ntaub ntawv roj teeb, tooj liab-impregnated graphite tau dav siv nyob rau hauv kev npaj cov roj teeb electrode daim hlau los txhim kho cov kev ua tau zoo ntawm cov roj teeb vim nws zoo heev conductivity thiab mechanical zog.

Hauv kev tswj hwm thermal, tooj liab-impregnated graphite tuaj yeem ua rau cov cua sov ua kom sov rau cov cua sov dissipation ntawm ntau yam khoom siv hluav taws xob. Vim nws zoo heev thermal conductivity, nws muaj peev xwm sai sai dissipate tshav kub, yog li ua kom lub sij hawm ntev kev ruaj ntseg ntawm cov khoom.

Hauv cov khoom siv hluav taws xob, tooj liab-impregnated graphite tuaj yeem siv los tsim cov capacitors, high-voltage oil-immersed transformers thiab lwm yam khoom siv. Vim nws cov conductivity zoo, nws muaj peev xwm xa hluav taws xob teeb liab thiab lub zog zoo, yog li nws tuaj yeem ua tau raws li qhov xav tau ntawm ntau yam khoom siv hluav taws xob.

Hauv kev tsim cov tshuab tsim, tooj liab-impregnated graphite tuaj yeem ua rau ntau yam duab ntawm daim hlau, kav, hmoov, thiab lwm yam, kom tau raws li ntau yam kev xav tau ntawm kev tsim khoom. Nyob rau tib lub sijhawm, nws hnav tsis kam thiab corrosion kuj tseem ua rau nws yog ib qho khoom siv zoo tshaj plaws.